What is a Thermal Expansion Tank?

A thermal expansion tank is a device designed to regulate the water pressure in your home’s plumbing system. When water is heated, it expands, creating potential for excess pressure in your pipes. This pressure surge can lead to leaks or even burst pipes. Thermal expansion tanks offer a solution by providing a space for expanding water, thereby preventing pressure build-up and potential damage to your plumbing system, including your water heater’s T&P Valve.

Open Loop vs. Closed Loop Systems

Understanding the type of water system in your home is crucial for determining the necessity of a thermal expansion tank. The two common types of systems are open-loop and closed-loop systems.

Closed-Loop Systems

Closed-loop systems are commonly found in homes that have a check valve in the water meter, a Pressure Regulating Valve (PRV), or potentially high water pressure outside the home (over 80 psi). This creates a true closed-loop system, which lacks a mechanism for water expansion and contraction during heating and cooling cycles. For homes with such systems, manufacturers strongly recommend the installation of thermal expansion tanks for warranty purposes. Thermal expansion tanks are particularly essential for these homes, as they provide a space for expanding water and help prevent pressure buildup.

New Installation Requirements for Thermal Expansion Tanks

Notably, the Kansas City Mo Water Department is replacing water meters with check valves. In this context, thermal expansion tanks play an even more critical role. Many homeowners in Kansas City Mo have reported their water heaters beginning to leak several months after the city replaces their water meter, a problem that can be mitigated with a properly installed and functioning thermal expansion tank.

Open Loop Systems

Open-loop systems are common in certain areas, including Olathe and most parts of Johnson County, where water meters typically do not have check valves.

For open-loop houses that do not have a check valve in the water meter, a Pressure Reducing Valve (PRV), or high water pressure (above 80 psi), a thermal expansion tank is typically not required. However, if a PRV is present or if the measured water pressure exceeds 80 psi, the system effectively becomes a closed-loop system and a thermal expansion tank is needed.

Considerations and Maintenance

While thermal expansion tanks offer numerous benefits, it’s essential to be mindful of potential issues. For instance, the tank’s butyl bladder with a polypropylene liner can degrade over time.

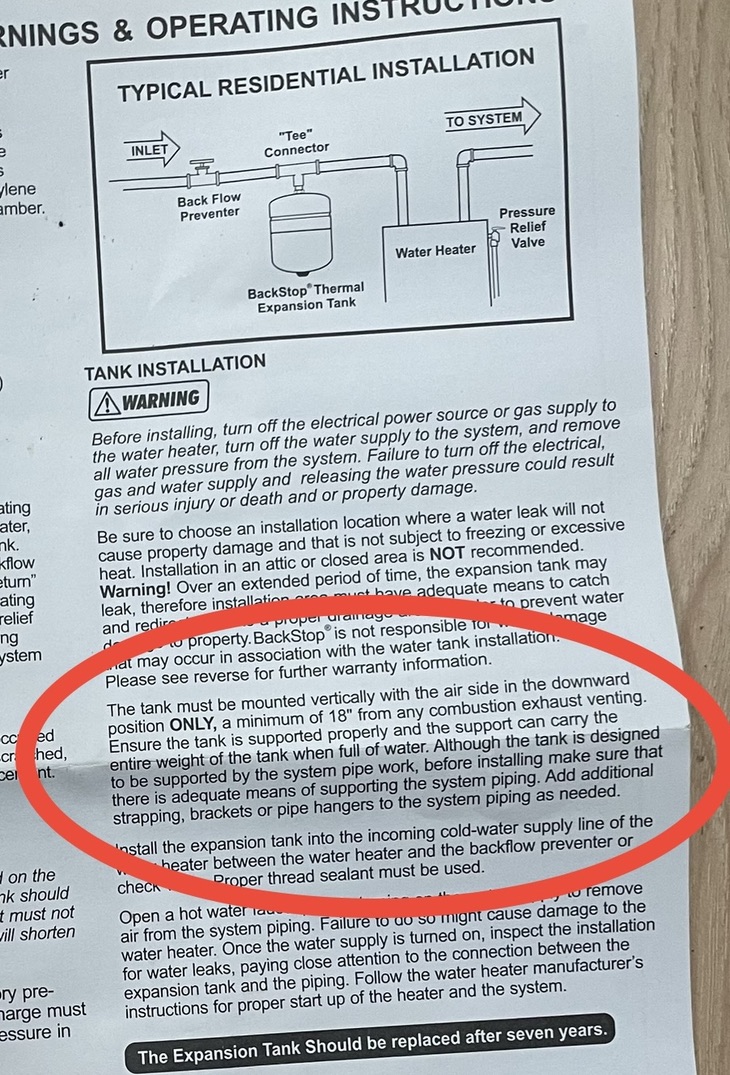

Installation is also a key consideration. Certain manufacturers, like Watts, allow for horizontal and even upside-down installation. However, Backstop and Amtrol now mandate that their tanks be installed with the valve facing downward. This change in policy comes after a study revealed an increased likelihood of wear and tear on the bladder, especially in the presence of significant sediment.

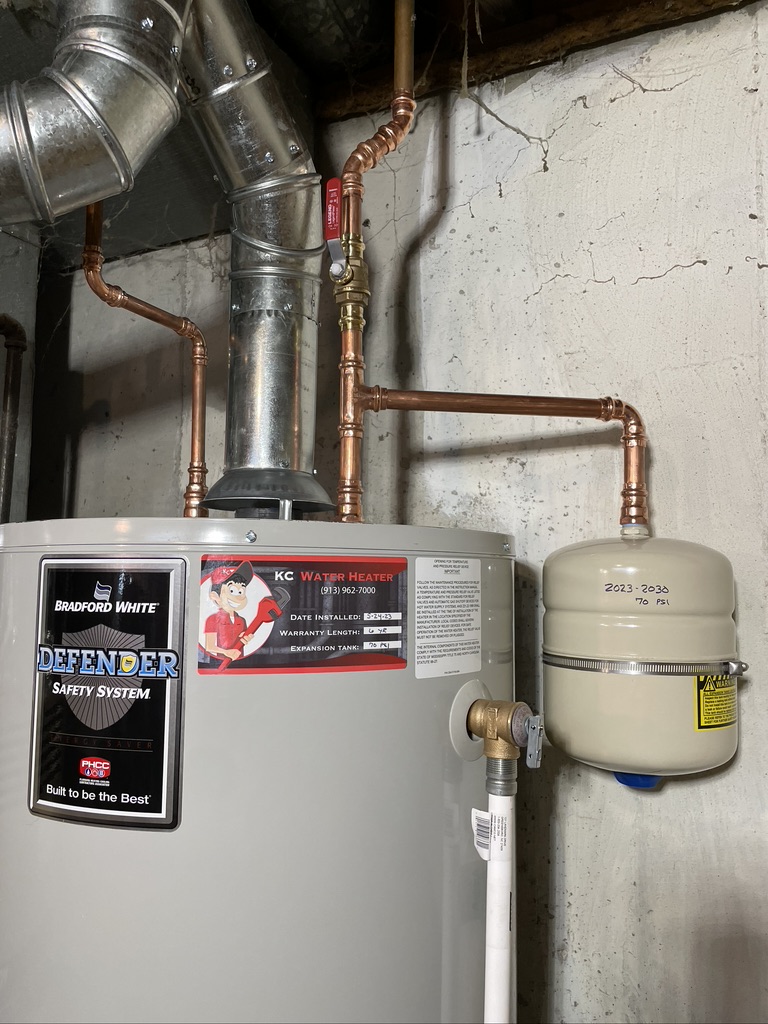

To extend the lifespan of the expansion tank, it’s important to match the water pressure accurately. Additionally, whenever possible, we recommend installing the expansion tank upright and at least 18 inches away from any gas water heater’s vent connector to prevent complications. It’s important to note that spillage from the draft diverter can potentially impact a thermal expansion tank. Always follow the manufacturer’s instructions for proper installation.

Thermal expansion tanks should be visually inspected every year and replaced every seven years or at the first sign of corrosion. Although you can check the pressure in the expansion tank, it may be best to leave it undisturbed. Adding air to a previously installed thermal expansion tank is not advisable. The system needs to be depressurized before attempting such a task.

(913) 962-7000 Call today!